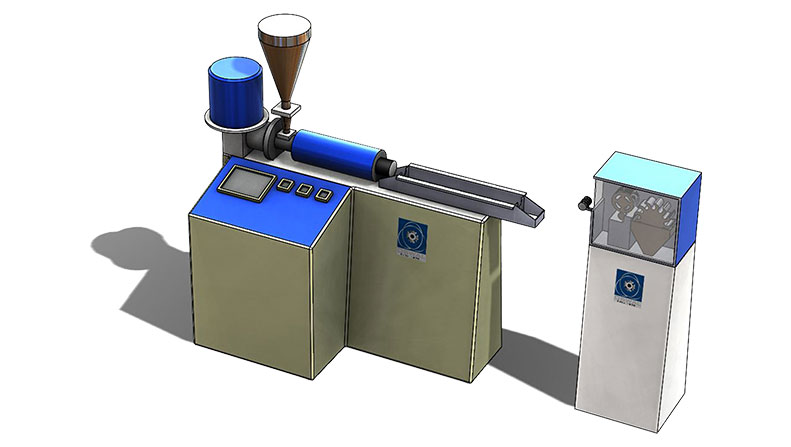

The OEC Lab Extruders are the ideal small batch extruder for practical and realistic solution for all industries. These Lab Extruders can process a wide variety of material and verifies performance expectations of production extruder. The Lab Extruders are widely used for R&D testing and low-volume production requirement.

There are virtually unlimited die configurations available. These Lab Extruders can be outfitted with optional system controls and cutting equipment. The customization is endless when it comes to the OEC Lab Extruders.

We as Oswal Engineering Corporation, have been offering highest standards of laboratory extruder machines to our clients in India and across the globe. We offer products as these lab extruders per the best suitable requirements and specifications of our valued clients. Thus we are counted amongst one of the reliable and trusted lab extruder machine manufacturers, suppliers in India having situated in Mumbai.

1. Same quantity of material used to do multiple tests

One of our clients produces its own master batch and has a constant requirement for new formulations and colours. They used to process all this in their 45mm compounding unit, which would easily gulp up 50 kgs in order to process the required parameters for the compound.

They came across our lab extruder and started using it. Their usage of materials dropped down considerably from 50 kgs to just 5 kgs, giving them ample time to adjust the parameters and try on new formulations in the same 50 kgs material.

2. Money saved

They process materials which cumulative cost of around Rs. 550/kg.

50 kgs of materials would cost Rs. 27,500/- for a single trial, apart from electricity required to operate and the space utilization of the machine.

With our Lab Extruder, the total cost of the same trial came to around Rs. 2,750/trial, saving around Rs. 24,750 or 90% of the cost. Apart from the material cost, the cost of processing also decreased as compared to heavy load requirement of 45mm extruder.

| Model No. | OEC 1125 |

|---|---|

| Screw Diameter | 25mm |

| Screw L/D Ratio | 22:1 |

| Screw Compression ratio | 1:3 |

| Main Drive | 1.5 kW A.C. Motor, with suitable A.C. Drive (ABB Make) and suitable gear box |

| Output | Up to 5 kgs/hr. |

| Screw RPM | 20 to 80 RPM |

| Heating load | 4 kW |

| 1. Extruder | 25mm single screw extruder mounted on M.S. fabricated body |

| (a) Screw | Made of SS304, polished with mirror finish |

| (b) Barrel | Made of high tensile alloy steel EN 41B, with nitride and hard chrome plating. |

| Heating zones | 2 nos. |

| (c) Hopper | Fabricated from SS 304 and has 2kgs capacity |

| (d) Die head | Customizable as per customer’s requirement |

| (e) Control Panel | Comes in two configurations: PLC control base or Manual PID type control base with sync cards |

| (f) Cooling through | Standard design made with SS 304 with recycling water system and stand |

| 2. Pelletizing unit | Cutting rotor made from D2 material 50 mm width for 2-5 strands cutting. |

| a. Motor | A.C. motor of 372W (0.5 HP) and suitable A.C.V.F. drive. (ABB make) |

| b. Output | 3 – 5 kgs/hr |

| 3. Electric Load required | 7kW 3 phase – 50 Hz 440V A.C. |

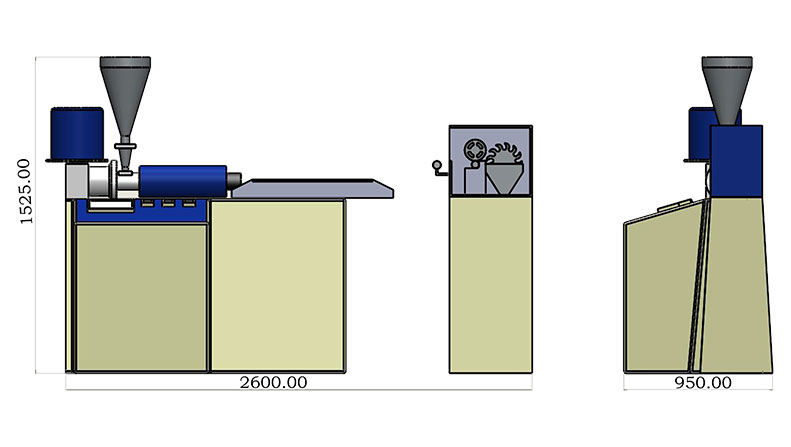

| 4. Space Requirement | 2800mm (L) x 1000mm (B) x 1500mm (H) |

Other ancillaries, like coiling unit or tube cutting unit (manual or pneumatic) are also available, and can be replaced with the pelletizing unit.